In the realm of industrial revolution, the convergence of Internet of Things (IoT) technology with industrial automation has birthed a paradigm shift. Industries are transforming, optimizing processes, and embracing smart manufacturing at an unprecedented pace.

Let’s delve into how IoT is reshaping this landscape, empowering businesses to thrive in the era of digital transformation.

Understanding IoT in Industrial Automation

IoT in Industry, Industrial Automation, Smart Manufacturing

The infusion of IoT in industrial automation is akin to breathing life into traditional manufacturing processes. By interconnecting devices, sensors, and systems, IoT enables the seamless exchange of data, fostering real-time monitoring, analysis, and decision-making. This synergy enhances operational efficiency, minimizes downtime, and elevates overall productivity.

Key Components of IoT-enabled Industrial Automation

IoT Devices, Sensors, Data Analytics, Connectivity

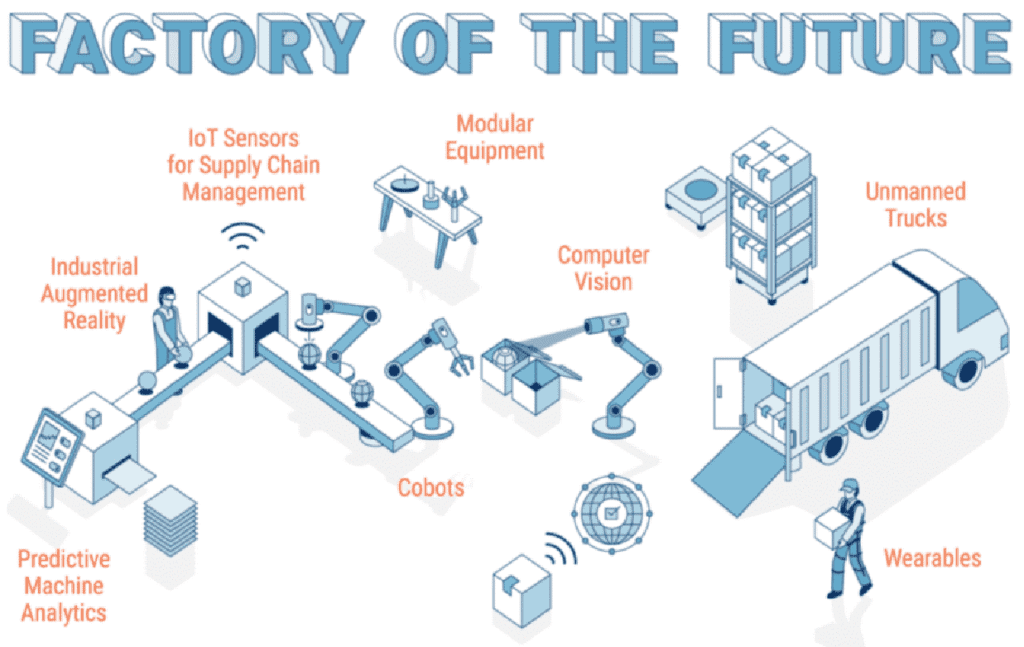

IoT-driven industrial automation relies on an ecosystem of interconnected components:

- IoT Devices & Sensors: Embedded sensors gather data from machinery and equipment, providing valuable insights into performance and condition monitoring.

- Data Analytic: Advanced analytics processes the influx of data, unveiling patterns, predicting maintenance needs, and optimizing workflows.

- Connectivity: Robust networks facilitate the transmission of data between devices and centralized systems, ensuring a cohesive operational framework.

The Impact on Smart Manufacturing

Smart Manufacturing, Industry 4.0, Digital Transformation

Embracing IoT in industrial automation births the concept of smart manufacturing, heralding a new industrial revolution (Industry 4.0). Smart factories leverage IoT’s prowess to create interconnected ecosystems where machines communicate seamlessly, enabling predictive maintenance, inventory optimization, and agile production processes. This convergence leads to reduced operational costs, enhanced quality control, and accelerated time-to-market.

Upskilling with Cranes Varsity: Online & Offline Courses

Cranes Varsity, Online Courses, Offline Course – IoT Training

To navigate this dynamic landscape, upskilling becomes imperative. Cranes Varsity offers a comprehensive suite of IoT Courses, catering to both online and offline learners. Their online courses provide flexibility, allowing professionals to learn at their pace, while the offline courses offer hands-on training in state-of-the-art labs, ensuring practical proficiency in IoT applications for industrial automation and smart manufacturing.

Conclusion: Embracing the IoT Revolution

The integration of IoT in industrial automation and smart manufacturing heralds a transformative era. As industries embrace this evolution, Cranes Varsity stands at the forefront, empowering individuals with the knowledge and skills needed to thrive in this tech-driven landscape. Through their tailored courses, they equip enthusiasts and professionals with the expertise to lead the charge toward a smarter, more efficient future.

IoT Revolution, Tech-Driven Landscape, Future of Industry

In conclusion, the marriage of IoT with industrial automation marks a pivotal chapter in the evolution of industries. With Cranes Varsity’s comprehensive training, individuals can ride this wave of innovation, driving the future of industrial excellence.

This blog aims to highlight the pivotal role of IoT in reshaping industrial automation and smart manufacturing while emphasizing the role of Cranes Varsity in empowering individuals through their IoT courses. Feel free to adjust or expand based on specific course details or additional information you’d like to incorporate.